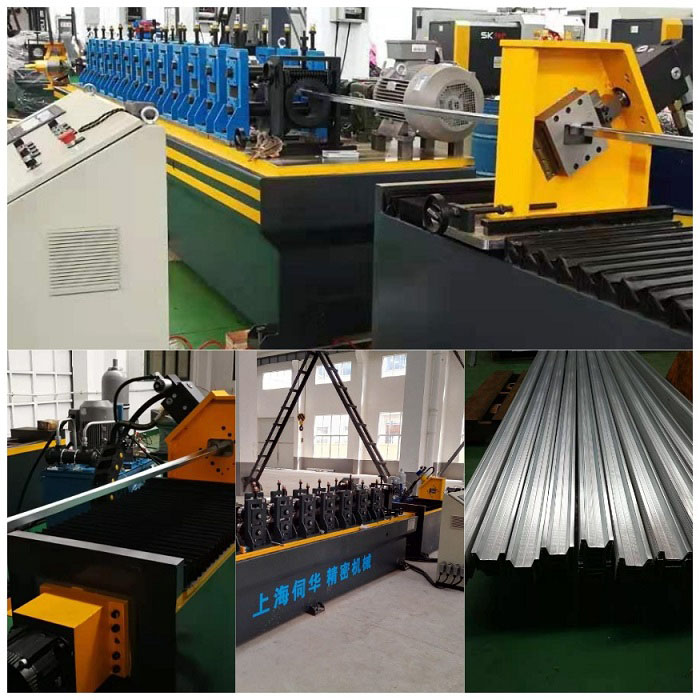

Likoloi tsa B profil ea koloi ea chassis e matlafatsang mohala oa tlhahiso

Sehlahisoa se ikhethileng sa tse tharo ho e le 'ngoe qalong se sebelisa taolo ea tsitsipano ea servo ho netefatsa phepelo e tsitsitseng ea lintho tse bonahalang, ha 16-roller precision leveler e felisa khatello ea lintho tse bonahalang. Ho feta moo, tsamaiso ea laser leveling e tiisa hore letlapa le bataletse ho mamella ho ≤0.1mm, ho rala motheo oa ho theha ka mor'a moo.

E na le mochine o moholo oa khatiso oa lithane tse 600 le punching e nepahetseng e shoa, e finyella ho nepahala ho phahameng ka ho fetisisa ho ± 0.1mm ka mekoting ea ho kenngoa ha leballo le khahlanong le ho thulana, ho felisa tlhokahalo ea ts'ebetso ea bobeli.

Precision punching die e bolela sesebelisoa sa boleng bo holimo se sebelisoang lits'ebetsong tsa litempe tsa tšepe ho phunya, ho phunya kapa ho phunya lisebelisoa tse nang le mamello e thata le liphetho tse ntle tsa bokaholimo.

Likarolo tsa Bohlokoa:

1.Ho nepahala ho phahameng - E boloka mamello e tiileng (hangata ka hare ho ± 0.01mm kapa ho feta).

2.Fine Edge Quality - E hlahisa likhahla tse hloekileng tse nang le li-burrs tse fokolang.

3.Durability - E entsoe ka tšepe ea lisebelisoa tse thata (mohlala, SKD11, DC53) kapa carbide bakeng sa bophelo bo bolelele ba tšebeletso.

4.Complex Shapes - E khona ho phunya lijeometri tse rarahaneng ka ho pheta-pheta ho phahameng.

5.Optimized Clearance - Punch-die clearance e nepahetseng e tiisa karohano ea thepa e boreleli.

Ts'ebetso e tsoelang pele ea li-pass tse 50, e ntlafalitsoeng ke software ea German Copra, e netefatsa hore tšepe e fetoha ka mokhoa o ts'oanang nakong ea ho kobeha ha serame. Mokhoa oa sebele oa ho shebella khatello ea kelello, o sebetsang hammoho le servo drive, o boloka mamello ea tekanyo ea ± 0.3mm karolong e nang le sebōpeho sa B. Liphetoho tse nepahetseng tsa arc likhutlong tse nepahetseng li thibela khatello ea maikutlo.

lintho tse bonahalang rolara: CR12MOV (skd11/D2) vacuum mocheso kalafo 60-62HRC

Mohala oa tlhahiso o na le mechini e 'meli ea welding ea laser ea TRUMPF ka khokahano ea mochini o habeli. Sethunya se seholo sa tjheseletsa se na le boikarabello ba ho kenya tjheseletsa e tebileng ho netefatsa matla, ha hlooho ea oscillating e sebetsana le manonyeletso a sekhutlo. Ho feta moo, sistimi ea tlhahlobo ea pono ea marang-rang e bona liphoso tsa weld ka nako ea nnete, ho netefatsa hore matla a weld a fihla bonyane 85% ea thepa ea motheo.

Selaoli sa rona sa ho kuta se tsoa Italy

Boemo bo nepahetseng bo phahameng bo khaola

Mamello ea Bolelele ba profil e phethiloeng ke 1mm ka pices